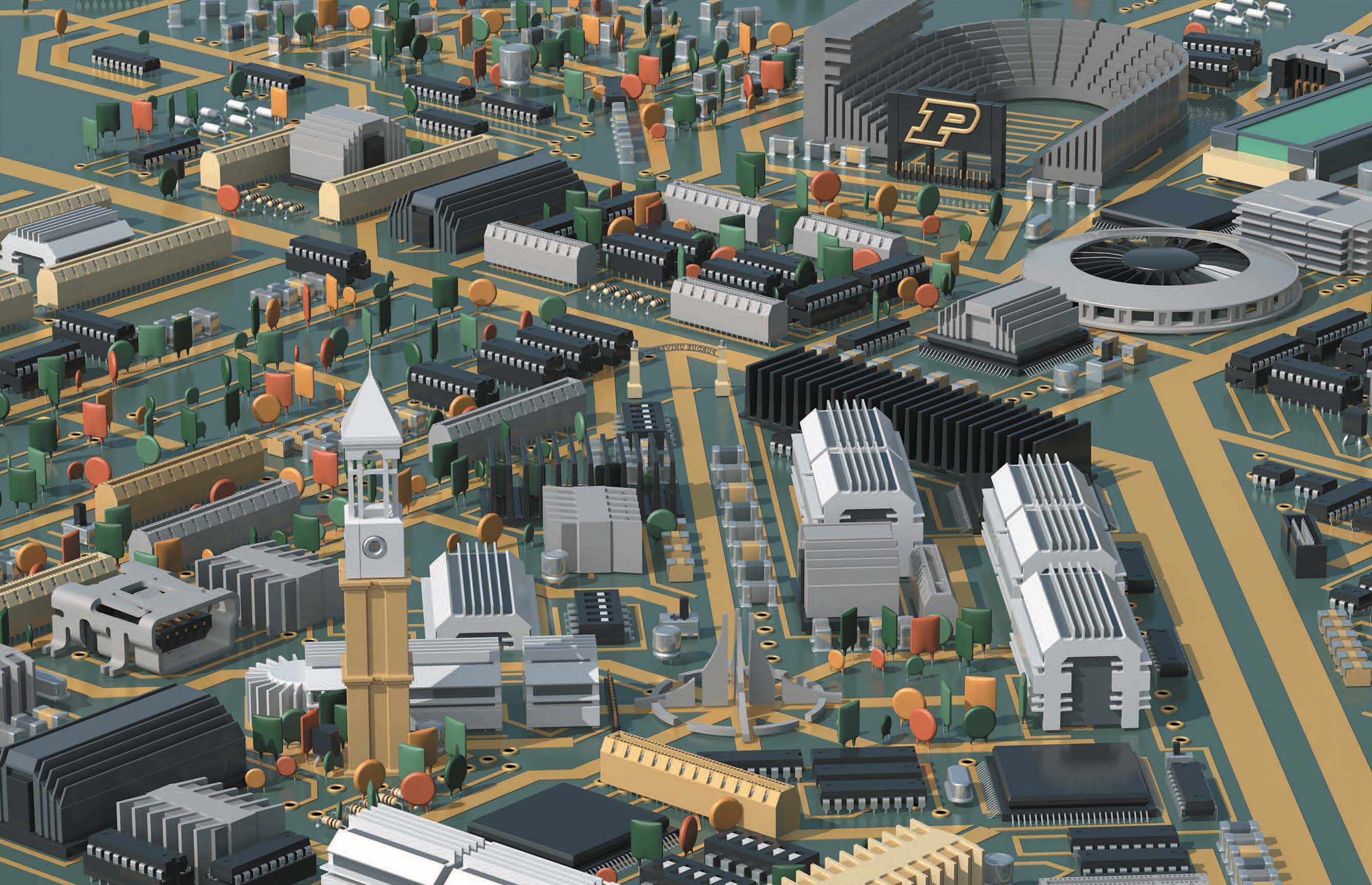

PIVOTAL MOMENT

Purdue students, researchers, and alumni have worked on the cutting edge of semiconductor technology since the 1930s.

That enduring commitment, along with a critical need to bring chip manufacturing back to the United States, positions the university for another history-making phase in the field.

The next giant leap will come through campuswide research and development efforts, along with the education of the next generation of engineers and technicians, which could have reverberations that extend from campus to the state, the nation, and the world.

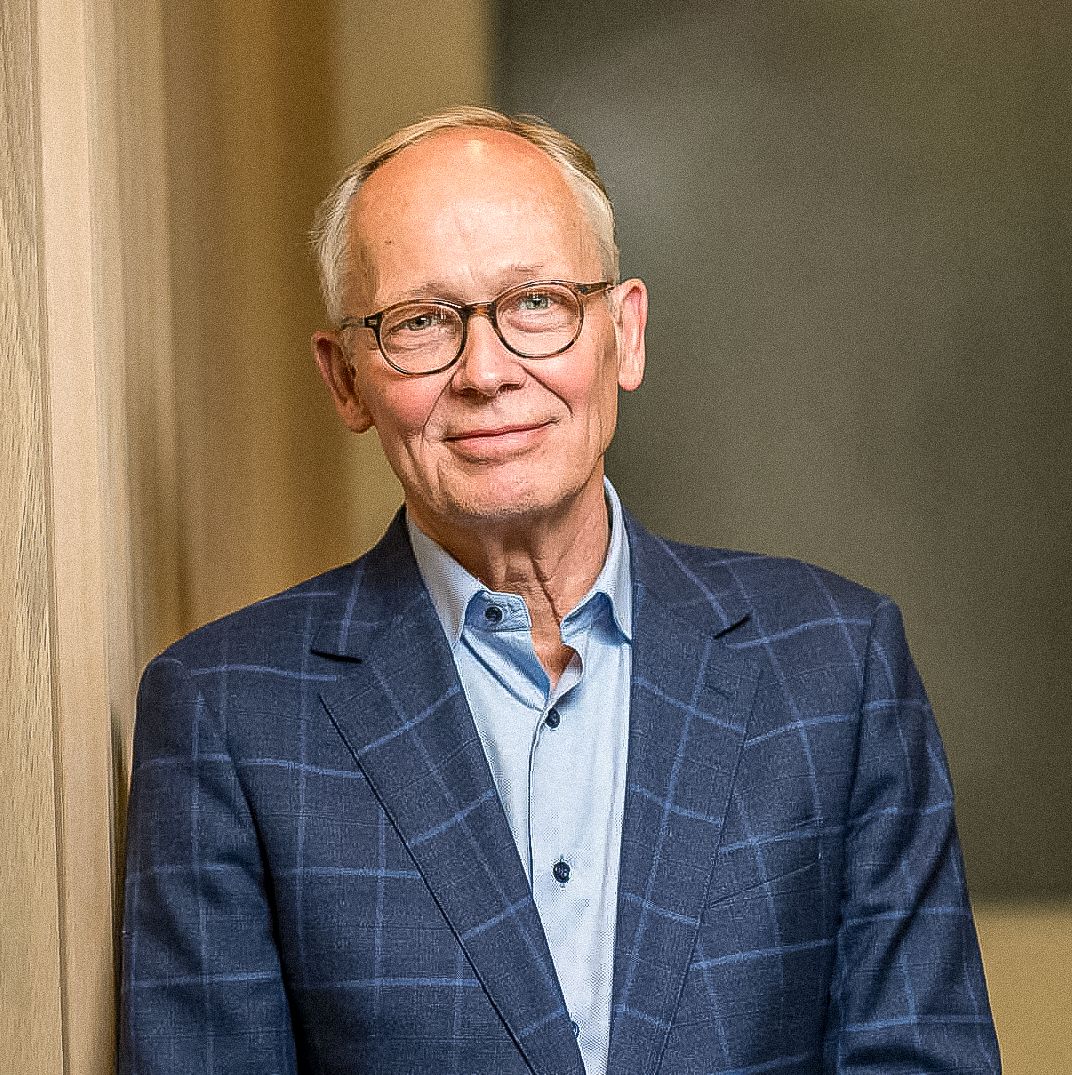

Mark Lundstrom (PhD ECE’80), the Don and Carol Scifres Distinguished Professor in the Elmore Family School of Electrical and Computer Engineering and Purdue’s chief semiconductor officer, thinks supply-chain issues during the pandemic may have awakened many Americans to the importance of microchips in almost every facet of life—smartphones, washing machines, automobiles, health care, and beyond.

“Everything relies on semiconductor technology, and we have outsourced about 90% of that manufacturing,” Lundstrom says.

The CHIPS Act, passed by the Biden Administration in August 2022, is offering more than $52 billion in subsidies for chip manufacturing, semiconductor research, and workforce training in the United States. Lundstrom, who has been embedded in the technology since his first days on campus in 1980, believes the time has come for a modern-day industrial revolution.

HISTORIC ANTICIPATION

Even as Lundstrom jokes that his family finally has a greater understanding of what he does for a living, Purdue’s long run in the field has been very intentional.

“We were really one of the powerhouses in semiconductor technology in the 1930s and ’40s,” he says.

This early research, centered in what was then the Department of Physics, was led by Karl Lark-Horovitz. Researchers developed techniques for growing high-quality semiconducting crystals made of germanium, Lundstrom says. Bell Labs, which was paying close attention to the work at Purdue, demonstrated the first transistor 75 years ago using those same techniques.

In the 1950s, John Atalla (MS ME’47, PhD ME’49, HDR E’03) coinvented the silicon MOSFET (metal-oxide-semiconductor field-effect transistor) at Bell Labs, which was then Bell Telephone Laboratories and is now Nokia Bell Labs. In December 2023, Purdue recognized Atalla’s pioneering role by naming the Atalla Institute for Advanced System Integration and Packaging in his honor.

“We’re a manufacturing state, and this is the most advanced manufacturing there is. It’s going to be a growing industry for the next 10 to 20 years or more.”

Mark Lundstrom

The Birck Nanotechnology Center, built at Purdue’s Discovery Park in 2005, helped further that innovative research. “There are only a handful of universities in the nation that have a facility like this,” Lundstrom says.

As federal funding rolls out to boost semiconductor manufacturing, Purdue looms as a promising location for future research. “Indiana is very interested in getting more of this industry in the state,” Lundstrom says.

STARS ALIGNED

Cristina Farmus (MBA’04), vice president of special projects and interim vice president for Purdue’s Office of Industry Partnerships, believes semiconductors represent a particularly special project at the university.

She has worked with many of the 80-plus faculty members to ramp up efforts in everything from workforce development to the securing of industry partnerships.

“The exciting part is that we’re capitalizing on something Purdue has been doing for a while,” Farmus says. “Though manufacturing has moved abroad, Purdue has persisted and maintained a critical mass of experts in the field.”

In May 2022, two months before the CHIPS Act was passed, Purdue launched a semiconductor degree program. The program will provide career opportunities for students in STEM fields, in particular. It is estimated that the industry needs more than 50,000 workers in the United States and as many as one million around the world.

“The need is tremendous—it’s across the board, from engineers to technicians,” Farmus says. “Purdue is doing its share to prepare talent for this national need. We also have a wonderful collaboration with Ivy Tech, and we’re working to build programs that will address industry needs for all their hires.”

Last summer, Purdue offered its first Summer Training, Awareness, and Readiness for Semiconductors (STARS) program. The eight-week program, intended to be the equivalent of a summer internship, is funded by industry and designed to attract students to semiconductor careers early on. According to Lundstrom, administrators were hoping to get approximately 50 students to participate. Nearly 500 students applied.

On April 3, SK hynix, a semiconductor supplier, announced plans to invest close to $4 billion to build an advanced packaging fabrication and R&D facility for AI products in the Purdue Research Park.

Considering such growth and interest in this burgeoning industry, Lundstrom envisions a “Silicon Heartland” on the near horizon.

“The impact of SK hynix is more than the creation of high-paying careers for Hoosiers,” he says. “Undergraduates will have opportunities for internships, co-op, and full-time employment when they graduate. Graduate students and faculty will work closely with SK hynix researchers, not only on basic research but also to accelerate the transition of research into pilot production and manufacturing. This is just the beginning. As other companies see what’s happening here in the heart of the heartland, they’ll come too, and a significant new cluster of semiconductor manufacturing and research will emerge.”